Briquette Press

Description

The briquette press is used to extrude waste materials, like wood and straw particles, paper, cloth, plastics, barks, sawdust etc. into briquettes. Briquettes are convenient to store, transport and burn. They are biomass fuel with high density. The cross sectional shapes of briquettes can be rectangle, octagon, hexagon, cylinder and so on.

Advantages

- The briquette press is made in China, which reduces the production cost.

- The briquette equipment adopts high-performance hydraulic extrusion device, so the blocks are smooth and strong with good compactness. It is easy to carry and store.

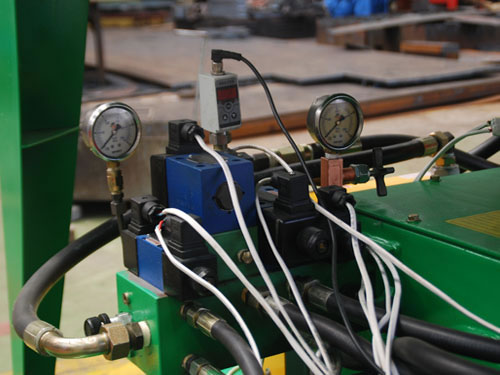

- The high-strength hydraulic system of the briquette press provides sufficient compressing power and contains the cooling system. It can assure the machine work stably.

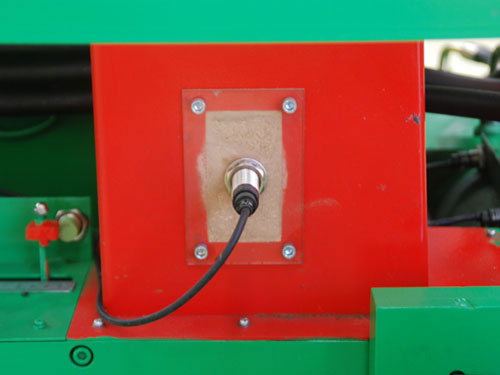

- The pressure cylinder adopts imported high wear-resisting material.

- Automatic rotating feeders of briquette equipment supply materials constantly to ensure stable and sustainable production

- Waste woods and straw can be compressed into certain shapes. What's more, there is no need to add any adhesive and additive.

- The briquette press has the function of adjusting thickness of briquettes. As to the shape, we can design specially for customers according to their requirements. In addition, the company's Logo can be graved on the briquettes.

Product Parameters

| Type | BPP-BP 125 | BPP-BP 250 | BPP-BP 500 | BPP-BP 1000 |

| Main Power (kw) | 7.5 | 15 | 37 | 75 |

| Capacity (kg/h) | 100-125 | 200-250 | 400-500 | 800-1000 |

| Dimension Length × Width × Height (mm) | 1960 × 1880 × 950 | 1960 × 1880 × 1950 | 2000 × 2000 × 2100 | 2700 × 2200 × 2300 |

| Weight (kg) | 1200 | 1700 | 4500 | 6800 |

After-sale Service

According to requirements of customers, we can send engineer and translators for installation and adjustment of the briquette press. They will assure the stable operation of briquette equipment. In addition, they will offer training to users until users can operate machines proficiently. Based on the experience, they will train users to maximize the capacity under the condition of stable operation of briquette equipment.

Packing and Transportation

Briquette presses are packed with waterproof polyethylene plastic film and wooden cases for external use. We adopt ocean shipping, land, air or sea-land transportation.

Shanghai Lanteky® Machinery Company has been specialized in making briquette equipment. It has cooperated with top European manufacturers for over 30 years and with research institution of Nanjing Forestry University in wood pellet line for years. Briquette press machines of Panda Pellet Company possess independent intellectual property rights and have applied for the national patent.

- SiloBiomass silos can be used to solve the problems of blocking during the feeding process, especially for soft materials. The texture of this kind of material is light and soft. Its mobility is bad. During the feeding process, blocking of material...