Three Rotors Hammer Flaker

Description

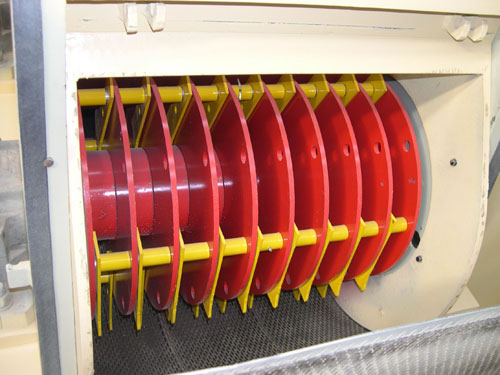

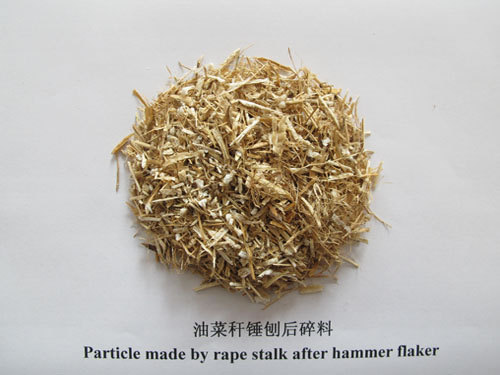

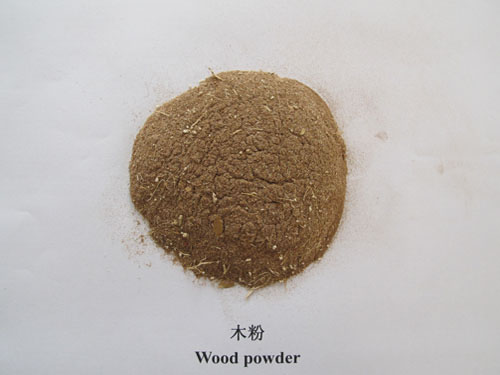

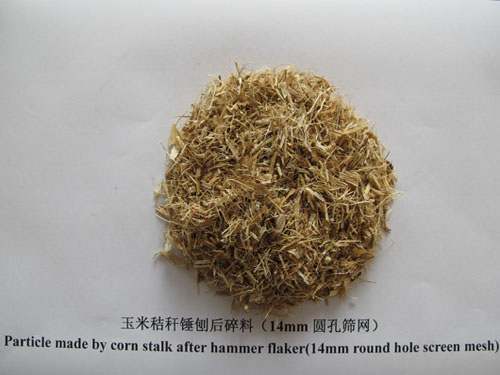

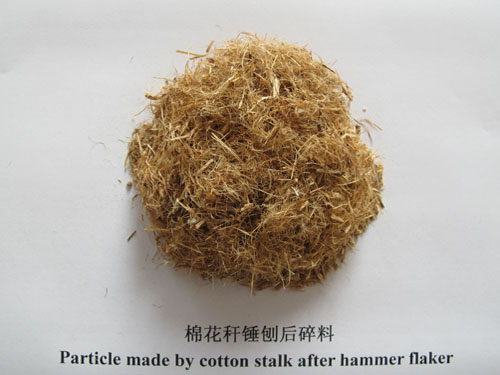

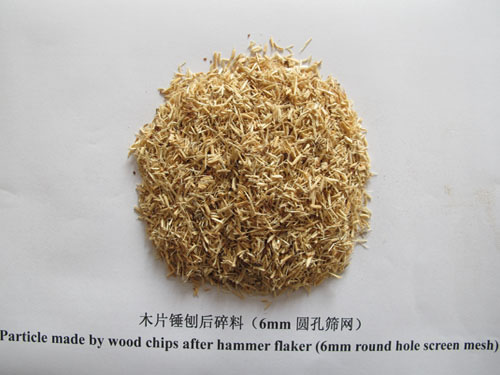

The three rotors hammer flaker is used to hammer waste veneers, chips, barks, oversized flakes after screening, crop straw, fruit shells, board edges of wood-based panels, reed, cotton stalks, palms, coconuts, etc. into fine shaving. Shavings processed by hammer planers have many applications. We can use them to produce pellets, briquettes and wood-based panels and for burning boilers. In addition, we can also grind those waste things into wood powder for manufacturing wood-plastic composites. Three rotors hammer flakers mainly consist of hammers, screens, rotors, planer tools, couplers, electro motors and engine bodies.

Advantages

- Key components of hammer flakers, like electrical machines, bearings, control elements use international brands. Special steels are imported. All of these offer guarantee to our products.

- We buy steels of the three rotors hammer flakers in China. Hammer planers are made in China, so the production costs are reduced.

- The hammer flaker has obtained the title of patented product. It is created based on the European equipment of its kind, keeping the original technology advantage.

Features of Three Rotors Hammer Flaker

- Three rotors installed inside of hammer flaker rotate relatively. Two rotors rotating in high speed crush the materials and the center rotor grind crushed materials to proper sizes. At the same time, ductile materials are cut to avoid winding.

- High wear-resisting hammers interplay with grinding blades. They can grind and cut the materials into fine stuff. Compared to traditional hammer flakers, the energy cost can be lowered over 47%.

- The three rotors hammer flaker has good adaptability and generality.

- The motor spindle drives directly with strong power and can rotate forward and backward.

- The imported SKF bearing has the function of self-lubrication, which can prolong its service life.

- Hammers are processed with heat treatment of the special metal and welded with high wear-resistant materials. Therefore, hammers are so sharp that they can increase the cutting force, prolong working life and decrease energy consumption.

- High-quality screen meshes of three rotors hammer flakers are made for special purpose. The shapes of shavings can be controlled by different screen meshes.

- The hammer planer is easy to maintain. The door can be opened from both sides. It also has the inductive safety lock.

- The vibratory feeder assures materials can be well-distributed at feeding opening. It can increase the stability of the equipment and make every wear-resistant components bear equal force.

- The spare parts include hammers, screen meshes, planer tool, etc. They can be replaced easily and quickly.

- Hammer flakers have high productivity, but the operating cost and energy consumption is very low.

- Three rotors hammer flaker adopts the lifting grinding blades. By adjusting the space of cutting area, shapes of shavings can be changed.

- It is installed stone remover and de-ironing separator to get rid of stone and iron.

Contrast

- The ring flaker is designed for common wet wood materials. When cutting raw materials with complicated shapes, like veneers and waste wood, the ring flaker works with low efficiency. The ring and the wear-resisting plate are seriously damaged and have to be replaced every few hours. Therefore, the machine has to be closed down for a long time. Shapes of shavings can not be assured. Three rotors hammer flaker has lower requirement about shapes and moisture content of materials. Spare parts of hammer planers can be bought with low price and used for long time. The operation cost is low. The flaker has high production capacity. The shavings from it are in good shapes.

- The screening ring polishing machines is main equipment during the particle board production. The production capacity of it is low, but energy cost is high. Screen meshes are very likely to be broken. The three rotors hammer flaker has a large shredding room and screen mesh. It is suitable for oversized shavings. Its production capacity is greatly increased.

After-sale Service

According to the requirements of the customers, we can send our engineers and translators for on-the-spot service. They can help with installation and adjustment of hammer planers until the three rotors hammer flaker operates safely and stably. Meanwhile, we will train users to maximize the production capacity on the condition of stable operation of machines.

Attention

Three rotors hammer flaker is used to hammer materials in small hardness, like timber, straw, waste paper, etc. If it is used to grind hard materials like coal briquettes, its hammer and screen mesh are liable to be broken.

Maintenance

- If there is metal, rock and other hard sundries in the raw materials of the three rotors hammer flaker, we should first get rid of them before shredding. In this way, we can prevent blades, screens and other components of hammer planers from damaging and avoid accidents.

- The use of high-performance magnetic selector is suggested for this magnetic selector can get rid of tramp iron and to prevent screen from damaging.

- The temperature of raw materials should not be higher than 50℃.

- For mordant materials, clear up work should be done to the three rotors hammer flaker after shredding. Lubricating oil and hydraulic oil should be replaced at regular intervals.

- Before every production, the screen mesh should be examined. If there is any damage, it should be replaced.

Packing and Transportation

The three rotors hammer flaker is packaged with waterproof polyethylene plastic film and wooden cases for external use. We adopt ocean shipping, land, or sea-land transportation.

Product Parameters

| Type | BPP-THF -5.5 | BPP-THF -7.5 | BPP-THF -11 | BPP-THF -15 | BPP-THF -18.5 | BPP-THF -22 | BPP-THF -30 | BPP-THF -37 |

| Main Power (KW) | 2 × 5.5 | 2 × 7.5 | 2 ×11 | 2 × 15 | 2 × 18.5 | 2 × 22 | 2 × 30 | 2 × 37 |

| Capacity (t/h) | 0.3-0.6 | 0.6-0.8 | 0.9-1.1 | 1-1.5 | 1.5-2 | 2-3 | 2-2.5 | 3-4 |

| Type | BPP-THF -45 | BPP-THF -55 | BPP-THF -75 | BPP-THF -90 | BPP-THF-110 | BPP-THF -132 | BPP-THF-160 | BPP-THF-200 |

| Main Power (KW) | 2 × 45 | 2 × 55 | 2 × 75 | 2 × 90 | 2 × 110 | 2 × 132 | 2 × 160 | 2 × 200 |

| Capacity (t/h) | 4-5 | 5-6 | 6-7 | 8-9 | 10-11 | 11-13 | 14-15 | 17-20 |

Three rotors hammer flakers are manufactured by Lanteky® Machinery In addition, we also offer shredders; dryers and so on. The company offers technology of biomass solidifying fuel production and complete equipment all over the world. We have a large number of users in this field.

- Bucket ElevatorThe bucket elevator is suitable for conveying powdery, granular, and lumpish materials vertically, like chips, sawdust, shavings, pellet fuels, etc. It can elevate materials up to 40m. The bucket lifter mainly consists of drive and tensioning...