Pellet Mill

Description

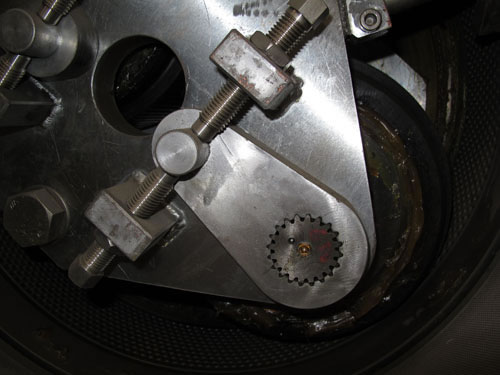

The pellet mill is used to process the wood or straw particles to pellet as biofuel. Key components of the pellet press include ring die, roller, modulator and motor.

Features

- Sawdust, shavings and straw are hard to be shaped. According to this, the major structure of BPP-PM pellet press has been redesigned. The enhancing of spindle system and improvement of lubrication system make the pellet mill strong and durable.

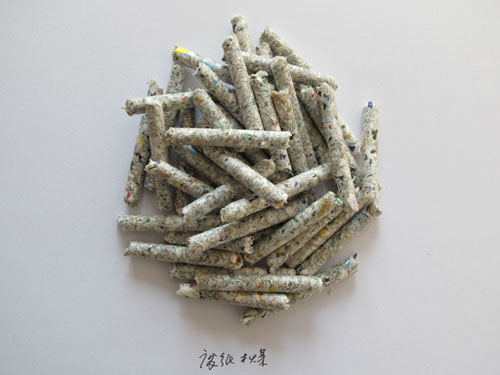

- The machine is suitable for different biomass materials. As long as the moisture content of materials is within appropriate scope, materials can be shaped into pellet fuel. The whole shaping process of pellet presses doesn’t need any adhesive or additive. Formed pellet fuel is beautiful with few flaws and equal length. In addition, it is of high density. Every technical index can achieve the international standard.

- Key components of the pellet mill, like ring die, , rollers, mixture of modulators use stainless steels to avoid rust. Compression rollers adopt special high wear-resistant tooth profile.

- The transmission systems of pellet presses with low power use bi-motor triangular belt. With simple structure, the pellet machine is easy to operate and maintain.

- Pellet mills with high power adopt synchronous belt drive. Electrical machines and ring die can be changed. Pellet diameters can be 6mm, 8mm, 10mm. If rubbish are used as materials to produce Rubbish Derivation Fuel, its pellet diameter can reach 24mm or larger.

Product Parameters

| Type | Main Power (kw) | Capacity (t/h) | Dimension Length × Width × Height | Weight (t) |

| BPP-PM-260 | 22 | 0.3-0.5 | 1050 × 1200 × 680 | 1 |

| BPP-PM-360 | 2 × 30 | 0.5-0.7 | 1600 × 1700 × 1170 | 3 |

| BPP-PM-460 | 2 × 55 | 1-1.5 | 1900 × 2230 × 1220 | 4 |

| BPP-PM-560 | 2 × 75 | 1.5-2 | 2500 × 2800 × 1860 | 6 |

| BPP-PM-660 | 2 × 110 | 2-3 | 2780 × 2520 × 1690 | 8 |

| BPP-PM-860 | 315 | 3.5-4.5 | 4100x 3180x 2280 | 12 |

| BPP-PM-960 | 400 | 4.5-5.5 | 4200 × 3245 × 2330 | 15 |

After-sale Service

According to requirements of customers, we can send engineer and translators for on-the-spot installation and adjustment. They will assure the stable operation of pellet mills. In addition, they will offer training to users until users can operate pellet press machines proficiently. Based on the experience, they will train users to maximize the capacity under the condition of stable operation of pellet mills.

Packing and Transportation

The pellet press is packed with waterproof polyethylene plastic film and wooden cases for external use. We adopt ocean shipping, land, air or sea-land transportation.

Pellet mills have its matched water detecting instrument, which can adjust the moisture content of materials automatically. Overloading protection device can assure the stable operation. In addition, doors of the pellet presses have safety protection switches so that the machine can not be opened during operation. All these advantages make pellet mills work safely with high efficiency.

- Bag FilterThe bag filter is a kind of dry-type dust filtration device. This kind of dust collector is suitable for get rid of small, dry and non-fibrous dust during the process of biomass fuel pellets production. The operating principle of bag filters is...