Disc Screen

Description

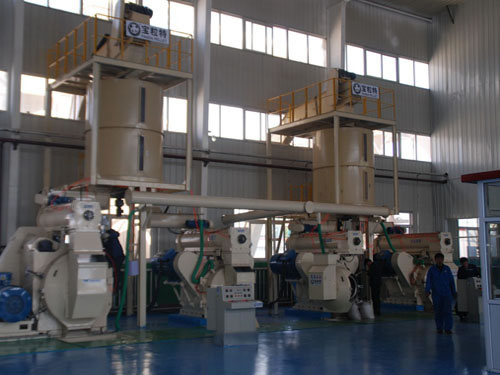

The disc screens, also known as roller screens, are suitable for screening chips, shavings, sawdust, crushed straw, etc. They are used to screen wet materials to 2-6 screening value. All space and discharging reverse turning bed can be adjusted freely. This adjustment can change size and quantity of screening value. The chain screening roller offers the sawtooth access to increase screening efficiency. The blocking of materials can be totally avoided. Disc screens can be used as the aspirator for getting rid of light pollutants, like plastics, nylon, textile, etc.

Features

- The screening efficiency of disc screen is high.

- The disc screen can work stably with low energy cost.

- The diamond disc screen is of good quality and has a long service life.

- Available screening value of disc screens can be perfectly corrected from superfine materials to oversize materials.

Advantages

- Panda Pellet Company has cooperated with top European manufacturers for over 30 years. It brings us with the vigor of quality and technology.

- Disc screens are made in China, which brings us price advantage.

- We have a team of expert engineers. They are ready to offer technology service for diamond disc screen to customers all over the world.

Payment, Packing and Transportation

We offer T/T and L/C payment.

Disc screen are packaged with vacuum waterproof polyethylene plastic films, and wooden cases for external use. We adopt ocean, land, air transportation or joint sea-and-rail transportation.

The Panda Pellet Company has cooperated with biomass-based fuel research institution of Nanjing Forestry University for years. According to materials with different properties, it has developed different screeners, like disc screens, oscillating screeners and vibrating screeners. Vibratory screeners are sold well all over the world and they are imported to Eastern Europe, Southeast Asia and South America.

- Annual Capacity 100,000t-Hebei Biomass Pellets Production LineThe scientific name of wood pellets is biomass solidifying fuels. They are made of renewable materials by shredding, drying, compression and other crafts. The raw materials of biomass pellets production line can be bamboo processing...