Annual Capacity 100,000t-Hebei Biomass Pellets Production Line

Description

The scientific name of wood pellets is biomass solidifying fuels. They are made of renewable materials by shredding, drying, compression and other crafts. The raw materials of biomass pellets production line can be bamboo processing residue, waste woods, crop straw, etc. Nowadays, energy is becoming less and less. The renewable clean wood pellet fuel shows its unique advantages in practical applicability, feasibility and universality. It is bound to be the new energy with large-scale and industrial development prospect. However, limited by technological development, market promotion and policy guidance, the development of biomass pellets production line is slow. It hasn’t entered the stage of normal industrial development.

Panda Pellet Company starts from the technical perspective of wood processing and devotes itself to developing and manufacturing wood pellets production equipment of high quality. Based on technique of artificial boards, the company supplies automation solutions of complete biomass pellets production line. After years of unremitting efforts, it has built more than ten wood pellet production projects with annual capacity over 50,000t in China. At the same time, wood pellet projects and equipment of the company are exported to Southeast Asia, Europe and achieve good reputation.

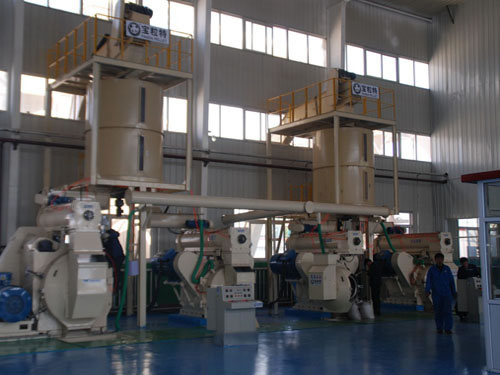

Hebei Fengning Hongsen wood industry has complete automation of biomass pellets production line. The annual capacity is 100,000t. The production line ranges from the shredding of different materials, drying in thermal power plants, online pellet mills, automatic packing by palletizing robots to modern master control room. The whole biomass pellets production line is the turnkey project of Panda Pellet Company. Meanwhile, in order to make wood pellets achieve European standards, the company specially introduces desanding cleaning system of Italy IMAL-PAL Group. This system can greatly reduce impurities of raw materials so that wood pellet fuels can fully achieve European standards.

Advantages of Pellets Production Machine

- The Panda Pellet Company has cooperated with world famous Italy IMAL-PAL Group, Energy Conservation Center of State Forestry Administration, Chinese Academy of Forestry, Nanjing Forestry University, Shanghai Forestry University, Northeast Forestry University, etc. It has done many experiments with these academic institutions.

- The company has more than 30 years experience in wood industry. In order to solve the problems of energy and environment, it develops biomass pellets production line.

Technical Parameters

| Specifications of Biomass Pellets | 6 mm, 8 mm |

| Annual Capacity (t) | 100,000 |

| Raw Materials | brush woods, chips, sawdust, shavings, straw |

| Required Area of Equipment Installation | 4000 m2 |

| Required Height of Equipment Installation | 8 m |

Pellets Production Machine

The annual capacity of Hebei biomass pellet production is 100,000t. Biomass pellets production line involves drum chippers, three rotors hammer flakers, disc screens, hot-blast furnaces, dryers, conveyors, silos, dust removal equipment, pellet mills, coolers, screener, packing machines and palletizing robots.

Since its establishment, Lanteky® Machinery adheres to taking the road of high-output and high-standard industrial development. Using advanced technology and experience of foreign countries, it has developed innovative equipment for wood pellet production. At the same time, the company undertakes the complete large-scale engineering design of biomass pellets production line at home and abroad.

- FanWe produce two kinds of draught fans, one is the common centrifugal fan and the other is the roots high pressure fan. Common fans are used to convey materials and collect dust. Roots high pressure fans are suitable for long-distance...